The market for tattoo machines these days is replete with a variety of quality tools for every taste and budget. All of them are divided into only 2 categories: induction and rotary. For those who have extensive experience as a tattoo artist, choosing the right option will not cause any problems, but for beginners it will be more difficult. What are the features of tattoo machines and how do both options differ from each other? Our experts figured it out.

Induction tattoo machines

Device, principle of operation

Induction machines for creating tattoos have long become classics, the standard of quality and style of work of a tattoo artist. True, there are some nuances that make this classic no longer so universal. But first things first.

The induction machine has a rather complex device and is represented by the following key elements:

-

- The induction coil is the “heart” of any induction type tattoo machine, thanks to which the movement of the working needle is possible.

- The induction coil is the “heart” of any induction type tattoo machine, thanks to which the movement of the working needle is possible.

-

- Hammer (striker) — the core of the coil attracts it, and then with a certain frequency the spring to which it is attached returns to its place. It is the interaction of the coil and the hammer that ensures the functionality of the entire device.

- Hammer (striker) — the core of the coil attracts it, and then with a certain frequency the spring to which it is attached returns to its place. It is the interaction of the coil and the hammer that ensures the functionality of the entire device.

-

- The frame is a kind of “backbone” on which all the working elements of the machine are attached. As a rule, it is made of steel or copper (sometimes represented by alloys).

- The frame is a kind of “backbone” on which all the working elements of the machine are attached. As a rule, it is made of steel or copper (sometimes represented by alloys).

-

- Capacitor — the main task of this element is the accumulation and rapid return of energy. It depends on him whether the tattoo machine will spark or not.

- Capacitor — the main task of this element is the accumulation and rapid return of energy. It depends on him whether the tattoo machine will spark or not.

Each of the presented working elements of the tattoo machine makes it unique. If you replace at least one working mechanism, the product will work differently. Therefore, masters who are aware of all the intricacies of the relationship of elements are so valuable, and they can fine-tune the tattoo machine for any request.

What is the working principle of an induction machine? When direct current passes through the turns of the induction coil, the core is magnetized. He, in turn, attracts the striker to himself — the spring opens. Then the core is demagnetized, and the spring inertially returns the striker back. This interaction ensures the reciprocating movement of the working needle.

There are 2 types of induction models:

-

- Liners are a sharp machine with a short, hard hit. The needle instantly penetrates and exits the skin. The resulting pattern is clear and even. This is not the best option for painting — you can severely damage the skin and leave scars on it.

- Liners are a sharp machine with a short, hard hit. The needle instantly penetrates and exits the skin. The resulting pattern is clear and even. This is not the best option for painting — you can severely damage the skin and leave scars on it.

-

- Shaders are ideal for dense, high-quality shading. The stiffness is less than that of the liner, and skin injury is also less. But at the same time, the shader does not have the “bite” of the liner, so it is not recommended to use it to draw the contour — the lines will turn out blurry.

- Shaders are ideal for dense, high-quality shading. The stiffness is less than that of the liner, and skin injury is also less. But at the same time, the shader does not have the “bite” of the liner, so it is not recommended to use it to draw the contour — the lines will turn out blurry.

By the way, outwardly liners and shaders may not differ at all, but their “stuffing” is different (for example, liners have smaller coils).

Important. Induction machines usually use one or two coils. The number of turns in this case may be different. Some mistakenly believe that the power of the device depends on them. But this is far from true. A significant role is played by the thickness and quality of the wire used on the core. For example, a shader with 10–12 turns is considered standard, although eminent tattoo machine manufacturers like Jimmy Whitlock use only 6–8 turns.

Advantages and disadvantages

Induction tattoo machines have 4 key advantages: power, speed, artistry and price.

Power

Compared to the rotary, the induction beats downright very powerful. And if the master has 2 machines at once — a shader and a liner, then in one pass you can make a contour and paint over a significant area.

Speed

Induction models cover large areas of a drawing very quickly. For example, an area that a slow rotor will paint over for a long time can be filled with paint 3 times faster with an induction tool.

Artistry work

Induction machines have no equal in creating a sharp contour and dense, juicy shading.

Price

Last but not least. Induction models of tattoo machines are cheaper than rotary ones (even if we take into account the fact that a pair of machines is needed at once for high-quality and convenient work).

But it was not without unpleasant features:

-

- Impressive weight — most induction models are rather bulky and, with a very long session, create considerable discomfort for the master: the hands are buzzing, the back starts to hurt.

- Impressive weight — most induction models are rather bulky and, with a very long session, create considerable discomfort for the master: the hands are buzzing, the back starts to hurt.

-

- Strong vibration — before purchasing a machine, it is recommended to test it in idle. If the hand begins to literally “walk” from vibration, the model in question is not the best option.

- Strong vibration — before purchasing a machine, it is recommended to test it in idle. If the hand begins to literally “walk” from vibration, the model in question is not the best option.

-

- Noisy — have the infamous hum. For beginner tattoo artists, working with an induction tool for a long time can be a real challenge. Experienced craftsmen over time simply stop noticing this noise.

- Noisy — have the infamous hum. For beginner tattoo artists, working with an induction tool for a long time can be a real challenge. Experienced craftsmen over time simply stop noticing this noise.

Rotary tattoo machines

Device, principle of operation

When the first rotary models of tattoo machines appeared on the market, they loudly declared themselves, becoming serious competitors to induction tools. And this is not surprising, because such devices have unique advantages and comfort for the master is one of them. But according to some criteria, nevertheless, rotors lose to induction machines.

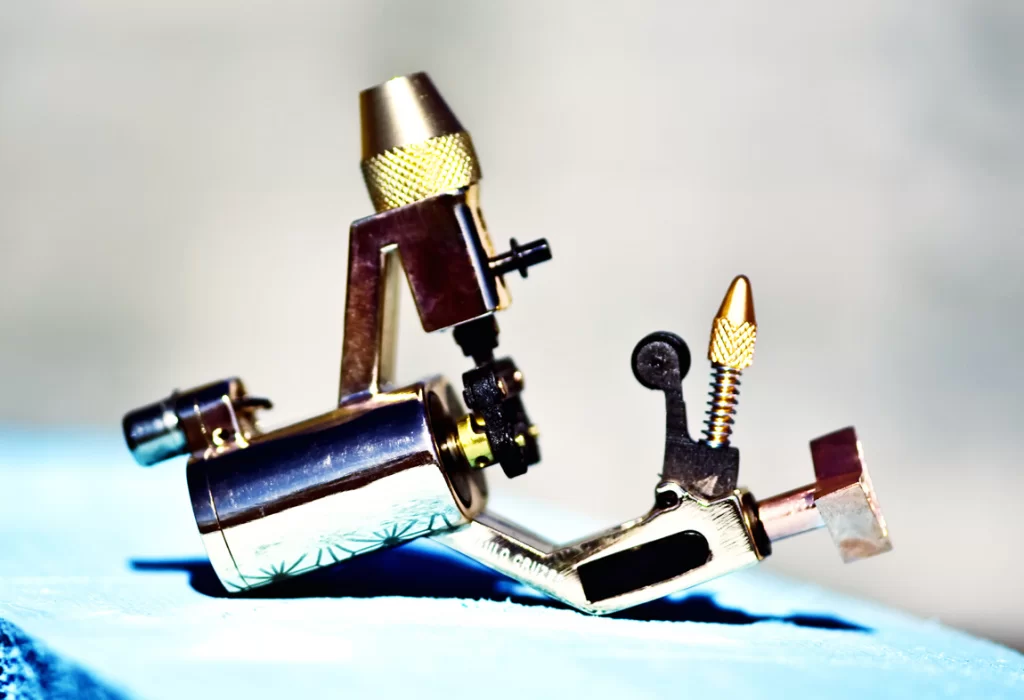

The rotor device is quite simple. If we consider it schematically, we can distinguish 3 main elements: an electric motor (rotor), an eccentric and a housing. The rotor is the most important part of the product. High-speed and powerful, but at the same time quite compact and lightweight.

An eccentric (a shaft with an offset axis of rotation) is installed on the rotor, the main task of which is to convert the rotational energy of the motor into the translational energy of the needle. Well, and, finally, the body. It’s a plastic/metal construction that makes all the components come together. Rotors-markers can be distinguished as a separate category. They are made in the form of a thick handle — expensive devices that are very convenient to work with.

When should you choose a rotary option? If you need to do work with an abundance of shadows, details, colors, but without large monochrome areas and clear boundaries. The rotor will cope with such a task perfectly well.

Advantages and disadvantages

Rotary tattoo machines are one of the market leaders thanks to a number of unique options:

-

- High efficiency — it’s all about the principle of operation of the electric motor built into the rotary tool. The rotor runs at a considerable speed and boasts high speeds.

- High efficiency — it’s all about the principle of operation of the electric motor built into the rotary tool. The rotor runs at a considerable speed and boasts high speeds.

-

- No impact and minimum vibration — due to the smooth movement of the needle, the vibration of the machine is reduced, respectively, the load on the hand in the process of creating a tattoo is also reduced.

- No impact and minimum vibration — due to the smooth movement of the needle, the vibration of the machine is reduced, respectively, the load on the hand in the process of creating a tattoo is also reduced.

-

- Noiselessness — rotary models practically do not create noise (compared to induction models, this is just a godsend).

- Noiselessness — rotary models practically do not create noise (compared to induction models, this is just a godsend).

-

- Versatility — one tool will help you create a shadow, and an outline, and a fill.

- Versatility — one tool will help you create a shadow, and an outline, and a fill.

-

- Ease — this makes the work (especially if the session is long) very convenient for the master.

- Ease — this makes the work (especially if the session is long) very convenient for the master.

-

- Adjustment of the rigidity and impact force of the needle — thereby minimizing skin trauma and increasing the comfort of working with the device.

- Adjustment of the rigidity and impact force of the needle — thereby minimizing skin trauma and increasing the comfort of working with the device.

Do not forget about the weaknesses of rotary machines:

-

- Not enough pigment in one application — there is no impact in the down position in the rotors, so the amount of paint applied in one pass of the needle is small. This leads to the need to pass one area of skin several times. The rotor is absolutely not suitable for painting large areas.

- Not enough pigment in one application — there is no impact in the down position in the rotors, so the amount of paint applied in one pass of the needle is small. This leads to the need to pass one area of skin several times. The rotor is absolutely not suitable for painting large areas.

-

- The inability to draw a contour — this is due to the smooth operation of the needle, which leads to a fuzzy contour. The clearer and sharper the movement of the needle, the better the contour. And here there are no equal to induction models.

- The inability to draw a contour — this is due to the smooth operation of the needle, which leads to a fuzzy contour. The clearer and sharper the movement of the needle, the better the contour. And here there are no equal to induction models.

-

- Insufficient speed — although rotary products are fast, nevertheless, their speed is insufficient — using rotors for large patterns is blasphemy.

- Insufficient speed — although rotary products are fast, nevertheless, their speed is insufficient — using rotors for large patterns is blasphemy.

-

- Rapid overheating / wear — as practice shows, rotary models fail more often and faster.

- Rapid overheating / wear — as practice shows, rotary models fail more often and faster.

-

- Expensive repairs — in the event of a breakdown, the repair of a rotary product will be quite expensive.

- Expensive repairs — in the event of a breakdown, the repair of a rotary product will be quite expensive.

Comparative characteristics

|

|

rotary machine

|

induction machine

|

|

Main purpose

|

Artistic, high-brightness multi-color work, drawings without much clarity, with an abundance of small details

|

Creation of a clear contour, painting over large areas of the skin

|

|

The weight

|

Minor

|

Significant

|

|

Vibration

|

Weak

|

strong

|

|

Noise level

|

Weak

|

High

|

|

Work speed

|

Medium

|

high

|

|

Depth of skin penetration

|

Minor

|

Medium

|

|

Ability to adjust settings

|

Yes (specifically hardness and impact speed)

|

Yes (impact force and frequency of needle movement)

|

Добавить комментарий

Для отправки комментария вам необходимо авторизоваться.