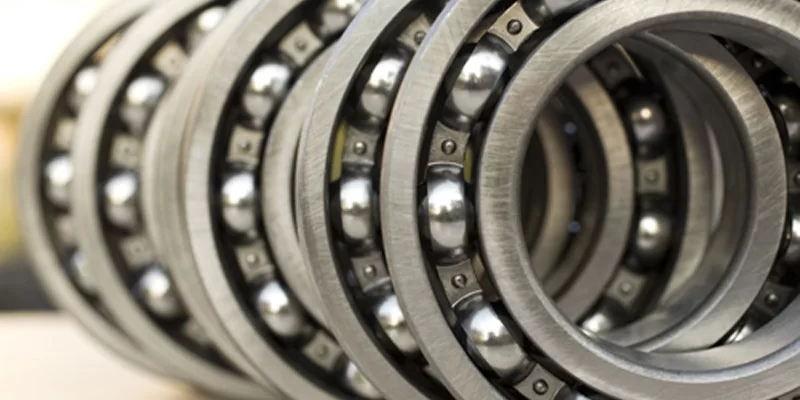

Any roller skates have several bearings, the number of which depends on the number of wheels in the design: each has 2 pieces. All bearings used in roller skates are standardized. Nevertheless, it is worth having at least a general idea about them, especially when it comes to the accuracy of their manufacture — this is the so-called ABEC classification. What is the difference between ABEC 5 or ABEC 7 and which is better? Our experts know the answer.

About quality bearings

All inline skates, without exception, have bearings in their design, and bushings are located between the wheels, the main task of which is to tightly fix between the bearings, transferring pressure from their inner rings to the frame. In practice, it looks like this: when rollerblading, the frame is alternately piled on the inside, and then on the outside. In this case, all the pressure is distributed over the frame, and does not go to the bearing. As a result, the latter fully functions under such a load and does not fail.

Speaking of roller bearings, one cannot fail to mention the so-called Swiss category — these are high-quality products that differ from classical ones in higher machining accuracy and the use of improved technologies (in particular, polymer cages, liquid lubricants, etc.). Manufacturers sometimes put the “Titanium” mark on such a product. The alloy of such products contains titanium, which significantly increases their endurance. Accordingly, the cost of production is higher.

There is another type of bearings — ceramic, the main difference of which from the standard ones is in the material used. In the classic version, the product is made mainly of stainless steel. The ceramic balls are created from silicon nitride. The ceramic version has a stronger structure and at the same time less weight. In general, we can say that it is ceramic ones that compare favorably with the classical ones. Their advantages:

-

Lightweight – On average, a ceramic bearing weighs around 9g, resulting in less centrifugal force acting on each ball. Accordingly, less energy is expended during friction.

-

High strength — the steel version will last much less than the ceramic one.

-

A smooth surface — again, helps to reduce friction.

-

Resistant to chemical attack — the material does not oxidize and practically does not need lubrication.

About ABEC standards

Almost all manufacturers indicate on the bearings they sell that they belong to a certain class according to the ABEC scale. The larger the number, the higher the accuracy will be. It is not about the use of a specific material. Bearings will be manufactured with a certain precision. The higher the class, the greater will be the rotational speed of the element (at the same time with a low friction index).

There are 5 accuracy classes, among which ABEC5 and ABEC7 are considered among the best. So, the first variety is an improved version of ABEC3, which is suitable for most varieties of high-quality inline skates designed for skating for fun without claiming to a professional level.

The ABEC7 is a racing variant favored primarily by experienced rollerbladers who are meticulous in their choice of product and surface. The products have a rather high price, which is associated with the complexity of manufacturing the product.

ON A NOTE. It should be noted that sometimes the difference between bearings of different classes is not very noticeable. This is especially true when the roller speeds up to 20 km/h. Vibration reduction can be noticeable at about 10,000 rpm. For example: the roller usually touches at a speed of no more than 2000 rpm. It is also impossible not to take into account that over time the bearing becomes clogged with dust, dirt, and wears out. Therefore, if you replace such a product with a product of a higher class, it may seem that the rollers ride better. In fact, the absence of dust in the element, the presence of clean lubricant, etc., play a role.

Comparison of bearing classes

Traditional debriefing. Our experts conducted a thorough analysis of both products and made a brief comparison.

|

|

|

|

|

|

Product of medium accuracy (error — 0.0035 mm)

|

High precision bearing (error — 0.0025 mm)

|

|

|

The level of rolling is low

|

Improved rollover

|

|

|

High stability

|

Low stability

|

|

|

Any other than liquid

|

Any other than liquid

|

What to choose?

First of all, you need to understand and accept one fact: at a speed of 30 km / h, there will be no difference between ABEC5 and ABEC7. In this case, it is difficult to say which ones roll better. If we are talking about the intricacies of operation, then ABEC7 will have to be serviced much more often than ABEC5. Simply put, the higher the class of the selected bearing, the more time and effort will be spent on caring for it to maintain its working condition.

If you are a professional inline skater and meticulously monitor the condition of the equipment, you should give preference to the improved version — ABEC7. With careful and competent maintenance, rollers with such bearings will provide the desired speed and excellent rolling.

If you are just taking your first steps in roller skating or can call yourself a confident amateur and do not plan to spend much time lubricating and cleaning roller skate bearings, ABEC5 is your choice.

Добавить комментарий

Для отправки комментария вам необходимо авторизоваться.