Builders often argue about which insulation is better to choose for certain conditions. Some say — polystyrene, others insist on the good old mineral wool. In general, both options are great for home insulation, since they have almost identical thermal conductivity coefficients. But other than that, they are radically different. Our experts understood the question: what is better — polystyrene or mineral wool?

Choosing the best

In order to accurately determine for yourself the optimality of a particular insulation, you need to clearly understand the features of each. Our analysts made a detailed comparison of both materials on a number of important criteria.

Life time

Some mistakenly believe that the foam becomes completely unusable after 7–10 years of service. In reality, such an unpleasant situation occurs only when the material is put into operation incorrectly, namely: in the absence of a protective coating. If it is, no rain or sun can adversely affect the foam. As for mineral wool, due to its structural features (material fibers are usually made with the addition of volcanic rocks), the impact of an aggressive environment does not in any way affect the state of the insulation.

Environmental friendliness

A few years ago, in the manufacture of foam, styrene was used as the base, and freon gas was used in the production process of this insulation. As a result, such material could not be used for finishing the interior living quarters of the house, since it emitted harmful gases. Currently, manufacturers have abandoned the use of freon in the manufacture of foam. Nevertheless, you should not get carried away with the amount of this insulation when decorating interior spaces. Mineral wool has no such restrictions.

combustibility

In this matter, mineral wool is the absolute leader — it simply does not burn. By the way, some varieties of this insulation (basalt) are able to withstand the effects of record high temperatures — up to 1000 0C. Expanded polystyrene will burn with a bright flame. It is known that flame retardants are added to the foam to prevent combustion. Only their properties gradually weaken and the insulation becomes unable to withstand fire.

Heat loss resistance

The thermal conductivity coefficients of both heaters are approximately the same. But, as practice has shown, polystyrene, nevertheless, is more reliable in this matter. Why? It’s simple: only dense basalt wool (slab) can compete in terms of thermal conductivity with expanded polystyrene, which cannot be said about rolled products.

Steam capacity

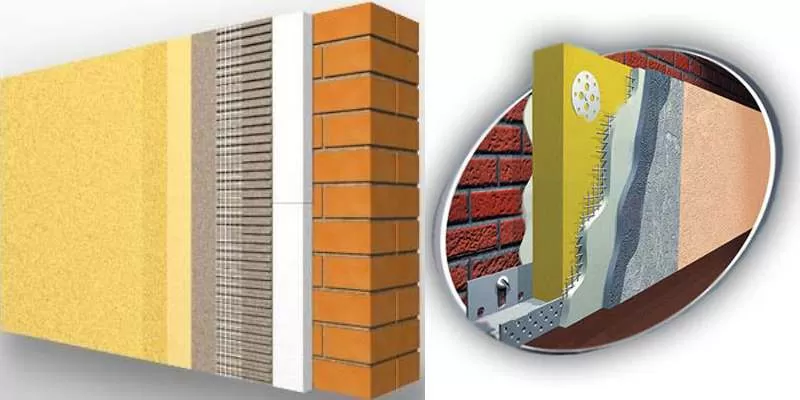

The coefficient of vapor permeability of the foam (regardless of the variety) is 0.3 mg / m.ch. Pa. A similar coefficient of mineral wool exceeds this figure by 10 times. And, therefore, it passes the evaporated moisture many times better. Practice has shown that usually the insulation of walls is multi-layered, and each layer has its own vapor transmission capacity. The final vapor permeability is evaluated by the material with the lowest value. In general, heaters are equated to each other.

It is impossible not to mention some features of both heaters. So, for an insulating system with a polymer structure, it is undesirable to use mineral wool, since both the base and the outer layer will not provide sufficient moisture passage. The rule is simple: material with better vapor barrier is laid closer to the outside of the house. Styrofoam does not let steam through, but does not accumulate either. From the inside, steam comes out only through the joints, defects in the finish. Whether this is a plus or a minus is hard to say.

Ease of installation

Both conventional and extruded foam are very resilient and strong, so there are no problems when sanding or breaking into fragments. But there are difficulties with fixing on the wall surface: cold bridges are almost inevitable at the junctions of individual elements. You can solve the problem by using sheets with an L‑shaped edge. As for mineral wool, it cannot boast of high density (except for mats laid in the facade). But she is completely unaware of any bridges of cold.

Features of the use of heaters

Not many people know that mineral wool and polystyrene foam can behave differently under different operating conditions. This means that both options are not always suitable for the same object.

Polyfoam is best suited in the following cases:

-

For basement-free houses with a monolithic foundation, foam plastic slabs are placed on a leveled area and poured with concrete.

-

For insulation of underground structures — polystyrene is not afraid of moisture from the ground, so it is best suited for such purposes. Even after decades, engineering structures will be reliably protected from the effects of cold.

-

For wall insulation in block / brick houses — the material will protect the premises from heat loss without the risk of a dew point (steam to moisture conversion).

-

For non-ventilated (warm, flat) roofs — foam plastic will perfectly protect such a structure from the cold, preventing the formation of condensate.

-

For insulation of floors — foam boards perfectly insulate both floors and floors with the obligatory use of an insulating layer.

Minvata are suitable in such cases:

-

For insulation of attics, pitched roofs — there is no better option than mineral wool (if there is ventilation).

-

For insulation of houses built of wood — for “breathing” walls, foam plastic is the worst option, since it actually levels out the useful properties of wood. Minvata is the perfect solution.

-

For warming low-rise brick houses — only if the mineral wool will act as a middle layer of thermal insulation.

-

For insulation of heated objects — mineral wool will perfectly protect against heat, withstanding temperatures up to 1000 0FROM.

-

For insulation of frame buildings — and the insulation is equally good for surfaces of different angles of inclination.

-

For covering partitions / ceilings in houses made of any materials.

Добавить комментарий

Для отправки комментария вам необходимо авторизоваться.